-

Plastic Profile Extruder Machine

-

WPC Profile Extruder Machine

-

PVC Profile Extruder

-

PVC Panel Production Line

-

PVC Pipe Production Line

-

PVC Sheet Production Line

-

PE Sheet Extruder

-

PP Hollow Board Extrusion Line

-

Plastic Pipe Production Line

-

Plastic Sheet Extrusion Line

-

Plastic Board Extrusion Line

-

Plastic Pelletizing Machine

-

Plastic Auxiliary Equipment

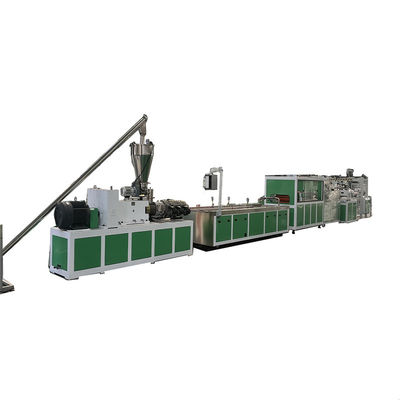

Speed Wide Usage Easy Operation PP Hollow Board Extrusion Production Line

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Features | Easy To Operate | Screw Diameter | 65-120mm |

|---|---|---|---|

| Core Components | Other | Heating Method | Ceramic Heater |

| Product Type | Extrusion Line | Transport Package | Container |

| Origin | Qingdao, China | Usage | Wide Usage |

Product Description:

The PP Hollow Board Extrusion Line has a wide range of usage in various industries, including construction, packaging, advertising, and transportation. The lightweight and durable characteristics of PP Hollow Sheets make them an ideal material for these applications. The extrusion line produces sheets with uniform thickness and smooth surface, which ensures the quality of the final product.

Our Extrusion Line comes with a Field Maintenance and Repair Service, ensuring that any issues that may arise during usage can be resolved quickly and efficiently. This service ensures that your production line is always up and running, maximizing the productivity of your business.

Investing in the PP Hollow Board Extrusion Line is a wise decision for businesses looking to produce high-quality PP Hollow Sheets in large quantities. Our product is designed with efficiency and reliability in mind, making it a valuable addition to any production line. Contact us today to learn more about the PP Hollow Board Extrusion Line and how it can benefit your business.

Features:

- Product Name: PP Hollow Board Extrusion Line

- Model No: SJ80-156

- After Warranty Service: Field Maintenance And Repair Service

- Width: 1200-2200mm

- Usage: Wide Usage

- Heating Method: Ceramic Heater

This PP Hollow Board Extrusion Line is perfect for manufacturing PP Corrugated Sheet Manufacturing Plant, PP Hollow Sheet Extrusion Machine, and Polypropylene Hollow Sheet Making Machine. It offers a wide usage and comes with a ceramic heater that ensures efficient heating. In addition, it is backed by a reliable field maintenance and repair service.

Technical Parameters:

| Origin | Qingdao, China |

| Product Type | Extrusion Line |

| Heating Method | Ceramic Heater |

| Product | PP Formwork |

| After Warranty Service | Field Maintenance And Repair Service |

| Screw Diameter | 65-120mm |

| Model No | SJ80-156 |

| Usage | Wide Usage |

| Features | Easy To Operate |

| Advantage | High Speed |

Applications:

The PP Hollow Board Extrusion Line is manufactured in Qingdao, China. The model SJ80-156 provides a high-quality output with excellent accuracy. The product is ideal for manufacturing polypropylene hollow sheets, which can be used in various applications. The product is versatile and can be used in a wide range of scenarios.

The PP Corrugated Sheet Manufacturing Plant is an excellent investment for businesses that require high-quality polypropylene hollow sheets. The product is designed to offer maximum efficiency and accuracy while minimizing the overall production cost. The product is ideal for use in different industries such as construction, agriculture, and packaging.

The Polypropylene Hollow Sheet Making Machine is an innovative product designed to meet the needs of customers. The product is manufactured using advanced technology and high-quality materials. The heating method used in the product is a ceramic heater, which ensures optimal performance and efficiency. The product is easy to use and maintain, making it an ideal investment for businesses of all sizes.

The PP Hollow Board Extrusion Line, PP Corrugated Sheet Manufacturing Plant, and Polypropylene Hollow Sheet Making Machine are packaged in containers to ensure safe delivery to customers. The products are durable and can withstand harsh working conditions. The products are backed by a comprehensive warranty, which provides customers with peace of mind.

The products are ideal for use in various applications such as packaging, construction, and agriculture. The products are designed to offer maximum efficiency and accuracy while minimizing the overall production cost. The products are versatile and can be customized to meet the specific needs of customers.