-

Plastic Profile Extruder Machine

-

WPC Profile Extruder Machine

-

PVC Profile Extruder

-

PVC Panel Production Line

-

PVC Pipe Production Line

-

PVC Sheet Production Line

-

PE Sheet Extruder

-

PP Hollow Board Extrusion Line

-

Plastic Pipe Production Line

-

Plastic Sheet Extrusion Line

-

Plastic Board Extrusion Line

-

Plastic Pelletizing Machine

-

Plastic Auxiliary Equipment

Pvc Wpc Plastic Wall Panel Machines Wall Panel Making Machine Wood Plastic Composite Production Line

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Screw Design | Double-screw | Screw L/D Ratio | 132:1 |

|---|---|---|---|

| Condition | New | Plastic Processed | PVC |

| Application | Sheet, Profile | Weight | 1800 KG |

| Warranty | 1 Year | Key Selling Points | Competitive Price |

| Applicable Industries | Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction Works , Energy & Mining, Food & Beverage Shops, Advertising C | Video Outgoing-inspection | Provided |

| Warranty Of Core Components | 1 Year | Core Components | Other |

| Machinery Test Report | Provided | Screw Material | 38CrMoALA |

| Screw Diameter (mm) | 65mm | Screw Speed (rpm) | 80 Rpm |

| Voltage | 380V 50HZ 3P | Dimension(L*W*H) | 4235*1520*2450MM |

| Power (kW) | 37 | Key | Ceiling Board ,sheet |

| Capacity | 150-350kg/h | Output (kg/h) | 150 - 350 |

| Highlight | Composite Wall Panel Making Machine,Plastic Wall Panel Making Machine,Pvc Wall Panel Making Machine |

||

PVC PROFILE EXTRUSION LINE

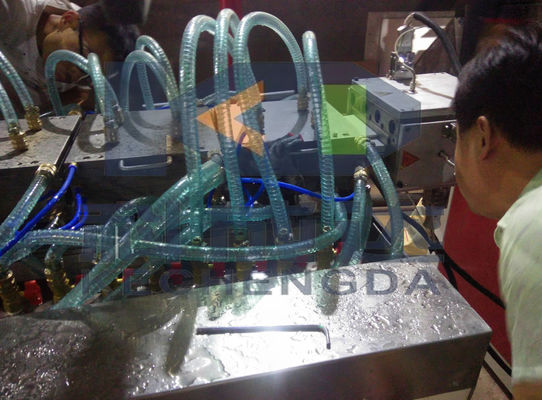

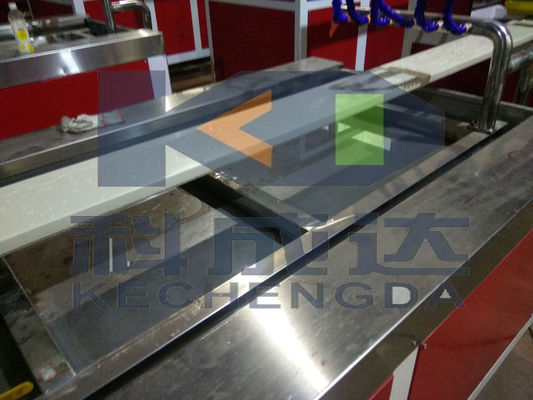

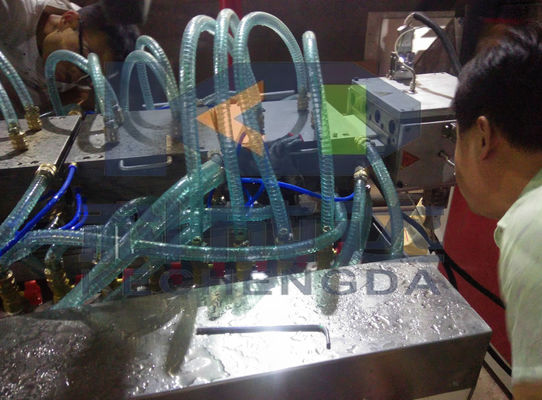

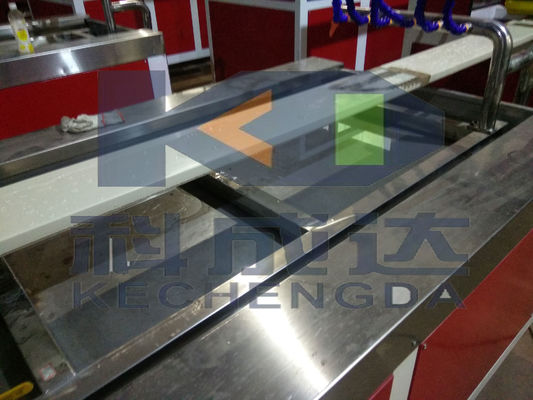

YF series PVC profile production line suitable to produce PVC profile multi-hole cable duct(4 hole, 6 hole, 7 hole, 9 holeoption), according to different profile section and mold to choose different conical or parallel twin screw extruder and provide relative vacuum sizing tank, haul-off, cutter, stack auxiliary equipment. The capacity of main extruder is from 150kg/h to 450kg/h for option. Special design for haul-off by particular up and down technology of our company, working table stable, reliable and heavy duty force. Vacuum sizing tank having particular big eddy flow cooling system for cooling and sizing easy for cooling and sizing easy for high speed extruding necessary.

3. Vacuum Calibration Tank

4. Haul-off

5. Cutter

6. Stacker