-

Plastic Profile Extruder Machine

-

WPC Profile Extruder Machine

-

PVC Profile Extruder

-

PVC Panel Production Line

-

PVC Pipe Production Line

-

PVC Sheet Production Line

-

PE Sheet Extruder

-

PP Hollow Board Extrusion Line

-

Plastic Pipe Production Line

-

Plastic Sheet Extrusion Line

-

Plastic Board Extrusion Line

-

Plastic Pelletizing Machine

-

Plastic Auxiliary Equipment

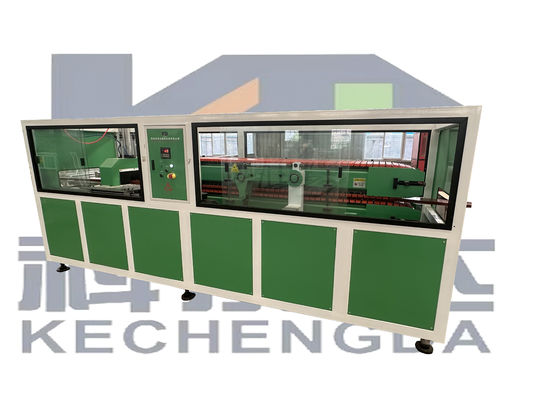

Wood Plastic Composited Product Making Machine/pvc Pe Pp Wpc Door Floor Decorative Profile Board Panel Extrusion Product

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Screw Design | Double-screw | Screw L/D Ratio | SJSZ 65/132 |

|---|---|---|---|

| Condition | New | Plastic Processed | PVC/WPC |

| Application | Sheet, Profile, Plates | Place Of Origin | Shandong, China |

| Weight | According Request | Warranty | 1 Years |

| Key Selling Points | High-accuracy | Applicable Industries | Building Material Shops, Manufacturing Plant, Farms, Home Use, Construction Works , Advertising Company |

| Screw Diameter (mm) | 132 Mm | Voltage | 380V (customizable) |

| Dimension(L*W*H) | According Request | Power (kW) | 500 |

| AC Contactor | Schneider/siemens | Temperature Controller | OMRON |

| Screw Materials | 38CrMoAlA | Control | PLC+Touch Screen |

| Final Product | WPC Floor/fence Etc. | Keywords | WPC Floor |

| Usage | Producing Wpc Profiles | Machine Name | WPC Floor Machine |

1.The WPC floor making machine can be used to produce wpc decking floor, fence, gazebo, benches, trash cans, etc.

2.The WPC floor making machine mainly consists of a screw feeder, a SJSZ65/132 conical twin-screw extruder, moulds, a vacuum setting table, a cutting machine, a stacker.

3.By changing different moulds, the same production line can be used to produce WPC profiles.

2. Customers specifying freight forwarders or negotiable shipping methods!

3. Delivery Time: 30 days after getting deposit from customer.

- provide customers with perfect service.

- our technicist will test each mould before they leave the factory.

- Our technicist are proffessional with more than 26 years experience.So that the mold debugging time is shorter than the other factorys.

- give the whole support for customer in raw material formula,selection of extruder

- machine,mould technique and operation training on the spot.

-

supply top-quality moulds and resonable price depends on customers requests(pictures or CAD drawing or samples).