-

Plastic Profile Extruder Machine

-

WPC Profile Extruder Machine

-

PVC Profile Extruder

-

PVC Panel Production Line

-

PVC Pipe Production Line

-

PVC Sheet Production Line

-

PE Sheet Extruder

-

PP Hollow Board Extrusion Line

-

Plastic Pipe Production Line

-

Plastic Sheet Extrusion Line

-

Plastic Board Extrusion Line

-

Plastic Pelletizing Machine

-

Plastic Auxiliary Equipment

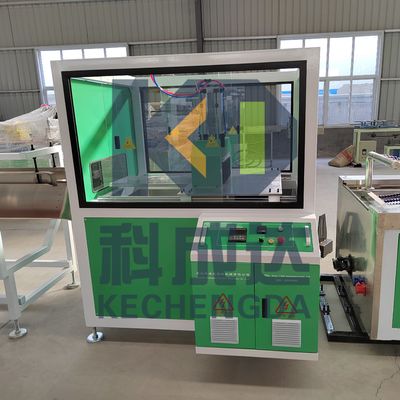

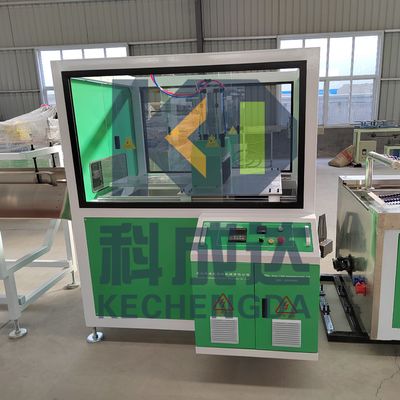

SJSZ - 65/132 PE PP WPC Extruder PVC Profile Extruder Machine

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Screw | Twin-Screw | Screw Channel Structure | Deep Screw |

|---|---|---|---|

| Automation | Automation | Brand | Qingdao Kechengda |

| Product Name | PP/PVC WPC Decking Extrusion Line | Item | Wood Plastic Extrusion Machine |

| Specification | SJSZ-65/132 | Origin | Qingdao China |

| Production Capacity | 12/Years | Assembly Structure | Integral Type Extruder |

| Highlight | Deep Screw wpc extruder,PE PP pvc profile extrusion line,Twin Screw pvc profile extruder machine |

||

| Engagement System | Full Intermeshing | |

|---|---|---|

| Exhaust | Exhaust | |

| Computerized | Computerized | |

| Material | PE/WPC/PVC | |

| Cooling Way | Water Cooling | |

| Transport Package | The Wooden Block Is Fixed with Steel Wire Wound | |

| Trademark | QINGDAO KCD | |

| HS Code | 84772090 |

PE/PP/PVC/WPC Profile Extrusion Machine/Plastic Extrusion Machine/Making Machine

Product Description

This extrusion line is suitable for producing co-extrusion PP/PE WPC decking. The decking surface can be made into wood grain by co-extruder. Furthermore, the machine can be equipped with on-line embossing device, the surface can be made into 3D wood grain. The WPC decking has a series of advantages including water-proof, insect prevention, ageing resistant, easy installation, environment friendly and good weathering resistance.

| Plastic Material | Recycle PP/PE Plastic |

| Wood Matreial | Wood Powder From Rice Husk/Straw,Wood Sawdust,Wastage Wood |

| Percentage Of Plastic | 25-30% |

| Percentage Of Wood Powder | 50-70% |

| Final Product | WPC Decking ,Wpc Wall Clading,Wpc Pergola Profile,Wpc Fence Profile And Other WPC Construction Profiles |

| Production Process | Raw Material-Mixing-Granulation-Extrusion and Molding-Surface Treatment |

1.WPC Granulation Machine

After get ready wood powder and recycled PP/PE plastic,The first step is mixing them with chemicals,The use WPC granulation machine to make WPC granules.

2.WPC Profile Extrusion LIne

The WPC profile extrusion line can make WPC granules into WPC products by equipping required mold ,we can equip co-extrusion system and online 3D embossing device for making WPC products in hight quality with wooden grain,the line also equipped with online cutting device.

WPC Product Wood Surface Making Machine

Embossing machine,sanding machine,brusing machine,online embossing machine.these machine is for making WPC products with better wooden feeling design.

High Quality Extruder in Workshop,WPC Door Extrusion Line,WPC Board Extrusion Line,WPC Profile Extrusion Line,WPC Decking Extrusion Line,Wpc Granulation Line.

Packaging & Shipping

Fastening of fixed Steel Wire with plastic Film wound Wood Block

Our Services

- We will provide the Feasibility Analysis Report for the wood plastic project.

- We will provide the model selection and technical parameter for wood-plastic machine.

- We will provide the design for the plant and electric powder accounting for the facilities.

- We will provide the design for wood plastic formula according to the product requirement.

- We will provide the technology of wood plastic product surface treatment.

- We will provide technique training for operator.

- We will provide solution for the practical problem during the production.

- We will install and test machine for free.

- We will provide turnkey project to customers.

We look forward to have the opportunity to work together with you in the future.