Brief introduction:

This production line is mainly used to produce PVC profile, such as ceiling panel, Deck, Floor, Cornice, Plank, Windows, Door frame and board etc.

If you think it only makes one product, you're wrong, by changing the molds, we can produce various shapes of profiles, such as ceiling panel, Deck, Floor, Cornice, Plank, Windows, Door frame and board etc.

According different customers detail requirement, you can choose which size you want and you like.

For the ceiling, the surface mainly adopts heat transfer-printing and most our customers like this way to do.

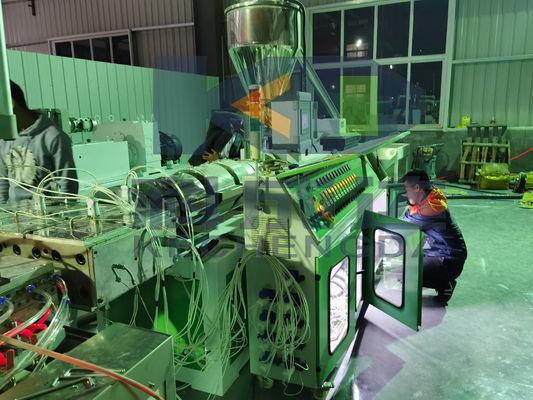

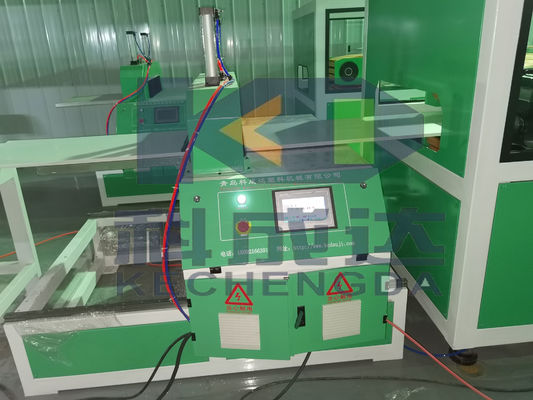

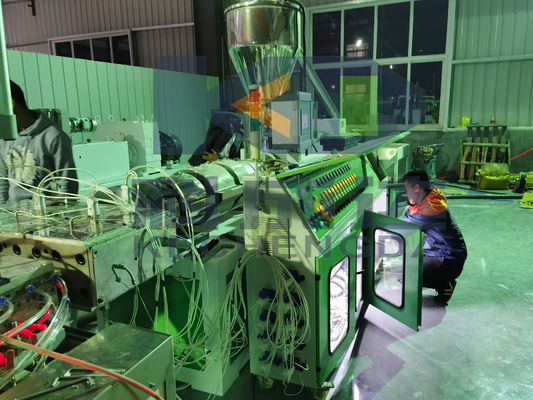

This plastic profile extruder production line adopts specially designed screw, barrel, mould. The extruder can match perfectly with the auxiliary machines and moulds.

The whole production line is of automatic control from the loading to the final discharging. The machines also can be manually adjusted separately. With the advantages of good plastication, low energy-consumption, high output, excellent performance, long life, etc.

It can be equipped with relative auxiliary equipment, such as vacuum calibration platform, haul-off machine, cutting machine, material reversal stacker. It is wildly used.

Material reversal stacker

Basic description