-

Plastic Profile Extruder Machine

-

WPC Profile Extruder Machine

-

PVC Profile Extruder

-

PVC Panel Production Line

-

PVC Pipe Production Line

-

PVC Sheet Production Line

-

PE Sheet Extruder

-

PP Hollow Board Extrusion Line

-

Plastic Pipe Production Line

-

Plastic Sheet Extrusion Line

-

Plastic Board Extrusion Line

-

Plastic Pelletizing Machine

-

Plastic Auxiliary Equipment

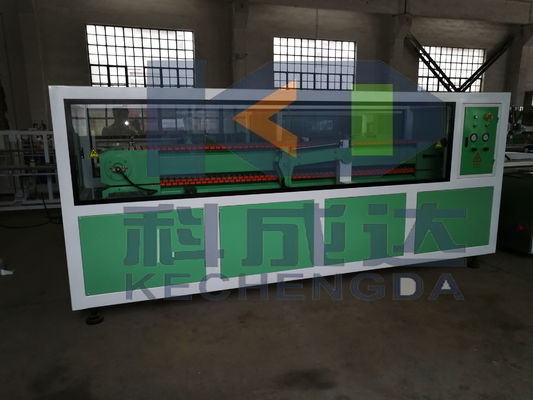

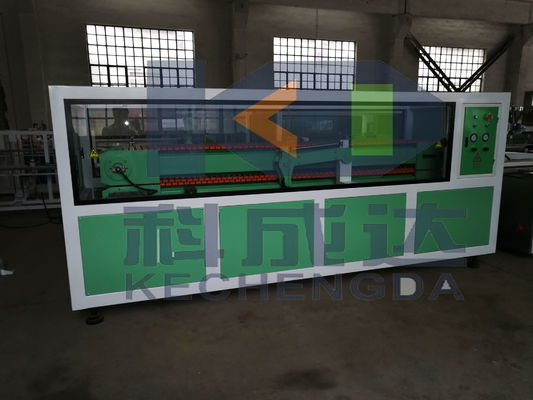

HDPE profile production line / plastic lumber making machine / plastic foaming profiles extruder

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Screw Design | Single-screw | Screw L/D Ratio | 30:1 |

|---|---|---|---|

| Condition | New | Plastic Processed | PE, HDPE, HDPE/PP, PE/PP |

| Application | Profile | Weight | 10 Ton |

| Warranty | 1 Year | Key Selling Points | High Productivity |

| Applicable Industries | Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction Works , Energy & Mining, Food & Beverage Shops, Advertising C | Video Outgoing-inspection | Provided |

| Warranty Of Core Components | 1 Year | Core Components | Bearing, Motor, Pump, Gear, PLC, Pressure Vessel, Engine, Gearbox |

| Machinery Test Report | Provided | Screw Material | 38CrMoALA |

| Screw Diameter (mm) | 75 Mm | Voltage | 380V |

| Dimension(L*W*H) | 23x3x2m | Power (kW) | 37 |

| Machine Type | HDPE Lumber Profile Extrusion Machine | Actual Energy Consumption Power | 80kw |

| Speed | 0.5-3 M/MIN | Power | AC380V,50HZ Or Customized |

| Water Supply | Water Used For Industry, No Impurities, By Filtrating | ||

| Highlight | HDPE profile production line,plastic lumber making machine,HDPE plastic foaming profiles extruder |

||

PVC WPC Production flow

Material:

Hdpe granules + chemicals+color pigment

Production Process

Mixing --Granulating- Extruding -- Mold -- Product -- Calibrating -- Hauling off -- Cutting -- Final products

Main machines:

Mixing machine,Granulating machine,extruder,mould, vacuum shaping platform,hauling machine,cutting machine,