It produce PVC ceiling wall panel with different size, such as 200mm, 250m,300mm, 400mm, 600mm and so on. (Material batching mixing-extruding-molding-vacuum calibrating and cooling-hauling-cutting- final PVC ceiling)

Technical Parameter

The basic machines needed for production of PVC ceiling wall panel:

-PVC mixer

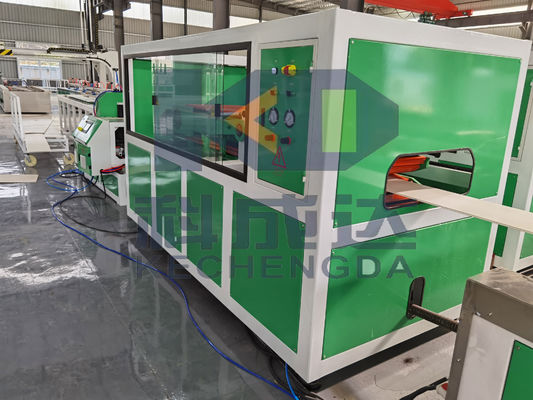

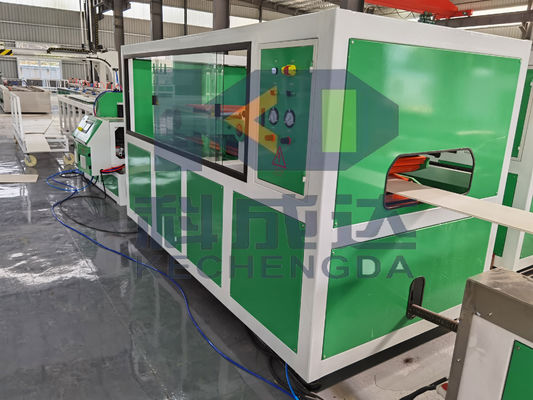

-PVC panel extrusion line

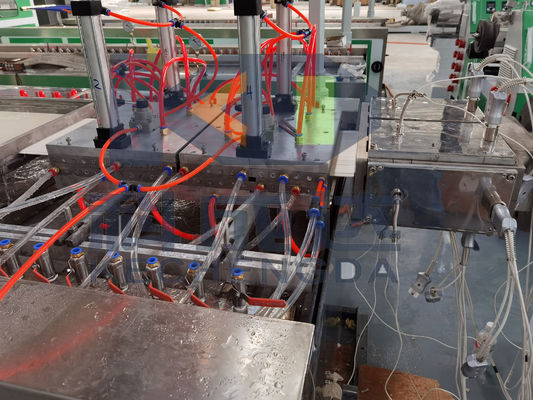

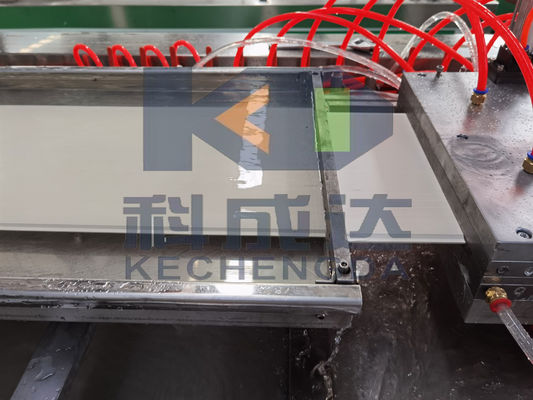

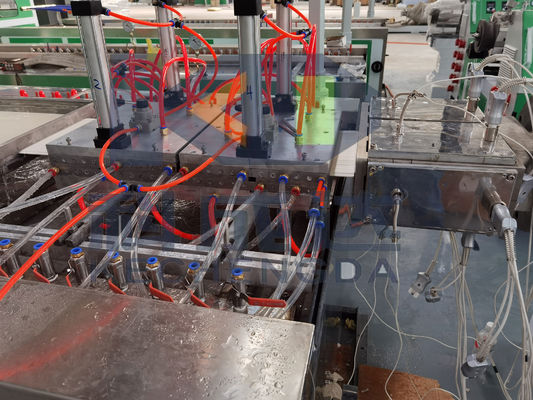

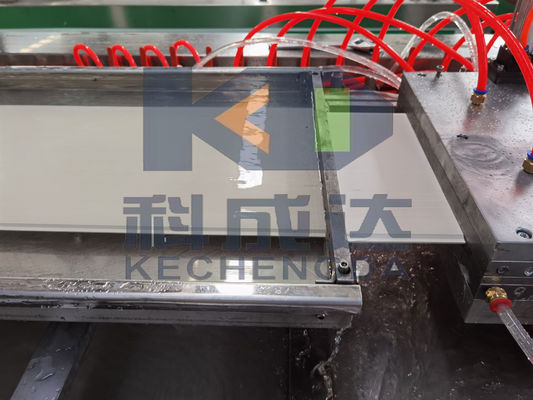

(Including autoloader, conical twin screw extruder, mould, vacuum calibration chamber, hauling machine, auto cutter- stacker)

- hot stamp printer or two color printing line or lamation

- PVC pipe crusher& PVC miller

- Air compressor

- Water chiller (optional)

- high glossy two color PVC ceiling wall panel printing line

-PVC panel extrusion line

(Including autoloader, conical twin screw extruder, mould, vacuum calibration chamber, hauling machine, auto cutter- stacker)

- hot stamp printer or two color printing line or lamation

- PVC pipe crusher& PVC miller

- Air compressor

- Water chiller (optional)

- high glossy two color PVC ceiling wall panel printing line