-

Plastic Profile Extruder Machine

-

WPC Profile Extruder Machine

-

PVC Profile Extruder

-

PVC Panel Production Line

-

PVC Pipe Production Line

-

PVC Sheet Production Line

-

PE Sheet Extruder

-

PP Hollow Board Extrusion Line

-

Plastic Pipe Production Line

-

Plastic Sheet Extrusion Line

-

Plastic Board Extrusion Line

-

Plastic Pelletizing Machine

-

Plastic Auxiliary Equipment

Automatic PVC Plastic Steel Door And Window Profile Extrusion Machine

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | PVC Plastic Steel Door And Window Profile Production Line | Color | Green,Other Colors Can Be Customized |

|---|---|---|---|

| Material | PVC | Capacity | 80-400kg/h |

| Control System | PLC | Power Of Main Motor | 22-55kw |

| Total Power | 55-110KW | Voltage | 220V/380V/415V/440V,Other Volatage Can Be Customized |

| Payment | T/T | Warranty | 1 Year |

| Highlight | Automatic PVC Profile Extrusion Machine,PLC Plastic Profile Extrusion Machine,400kg/h Plastic Profile Extruder Machine |

||

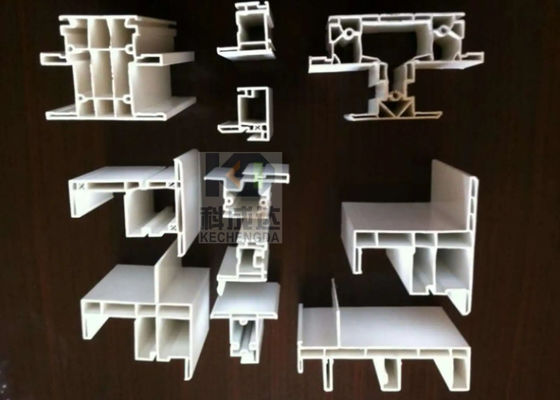

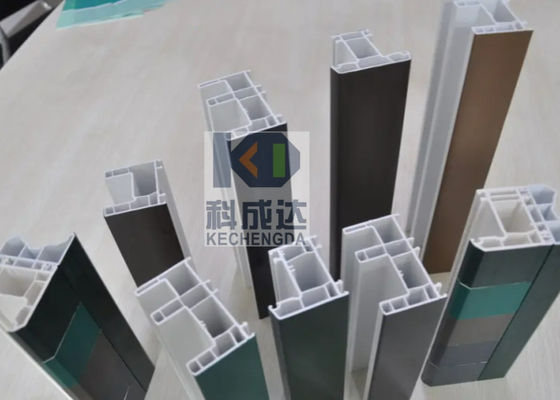

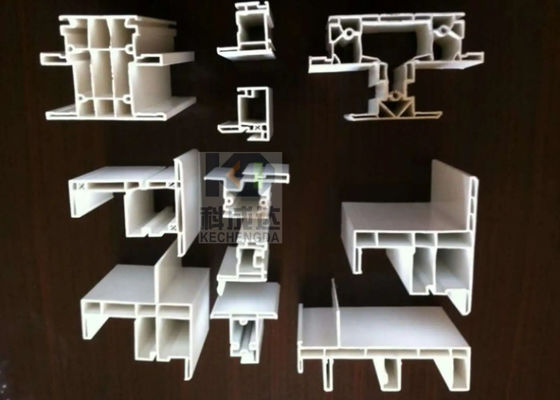

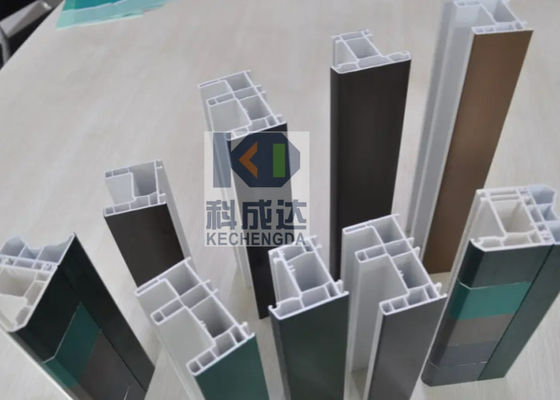

PVC plastic steel door and window profile production line

1. Production Introduction

PVC plastic steel door and window profile is a composite material that combines PVC material and steel. It has the characteristics of good weather resistance, sound and heat insulation, anti-corrosion, and easy cleaning. It is widely used in building doors, windows and curtain wall systems.

2. Production Feature

(1) Efficient production: The PVC plastic steel door and window profile production line adopts automated equipment and processes to achieve efficient production. Automated operations and continuous production processes can greatly improve production efficiency and reduce labor costs and time waste.

(2) Flexibility: The PVC plastic steel door and window profile production line is flexible and can be adjusted and customized according to customer needs and market changes. The parameters of the extruder can be adjusted, and the design of the mold and extrusion head can be changed to meet the production requirements of door and window profiles of different sizes, shapes and configurations.

(3) High-quality products: The PVC plastic steel door and window profile production line is equipped with advanced extruders and molds, as well as a quality control system, which can monitor and adjust the production process in real time to ensure product quality and consistency. By controlling the temperature, pressure and speed of the extruder, high-quality door and window profile products can be obtained.

(4) Energy saving and environmental protection: The PVC plastic steel door and window profile production line uses PVC material. PVC is renewable and recyclable, and there is no emission of waste gas, waste water and waste materials during the production process, which has low energy consumption and environmental impact.

(5) Multifunctional production: The PVC plastic steel door and window profile production line can produce door and window profiles of various shapes and configurations, such as right-angled window frames, curved window frames, door leaves, etc. By changing the mold and extrusion head, product production of different shapes and specifications can be achieved.

(6) Precise control: The PVC plastic steel door and window profile production line is equipped with an advanced control system, which can achieve precise control and adjustment of the production process. By controlling the parameters of the extruder, such as temperature, pressure, speed, etc., the size and performance of the product can be precisely controlled.

(7) Automated operation: The PVC plastic steel door and window profile production line adopts automated operation, which reduces the need for manual operation and improves production efficiency and product quality stability.

3. Product Configuration

![]()

| Equipment Model | Motor Power | Capacity | Total Power |

|

KSJSZ-51/105 |

22KW | 80-150kg/h | 55KW |

|

KSJSZ-65/132 |

37KW | 180-240kg/h | 80KW |

|

KSJSZ-80/156 |

55KW | 350-400kg/h | 110KW |

Note: In addition to the above configurations, our company can also customize according to customer needs.

4. Payment:

30% as advance payment by T/T after signed contract; 70% as balance before delivery by T/T .

5. The seller will provide the actual electric, pneumatic, hydraulic, mechanical parts circuit diagram for each unite of the machine with English language in addition to the original operation manual of the machine that contains the operation instruction, safety instruction, and troubleshooting with parts list for easy order necessary spare parts in the future.

6. Test run in the buyer’s factory: Seller send engineer for supervision of installation, training and test. The test will be finished in about 7-10 days if necessary preparations are made by the buyer such as water, electricity. Materials, work space, labors and so on. The round airplane tickets, visa cost, food, hotel fee and medical insurance of the engineer for installation and test run are paid by the buyer. The buyer pay USD150/per day as subsidy for the engineer.