-

Plastic Profile Extruder Machine

-

WPC Profile Extruder Machine

-

PVC Profile Extruder

-

PVC Panel Production Line

-

PVC Pipe Production Line

-

PVC Sheet Production Line

-

PE Sheet Extruder

-

PP Hollow Board Extrusion Line

-

Plastic Pipe Production Line

-

Plastic Sheet Extrusion Line

-

Plastic Board Extrusion Line

-

Plastic Pelletizing Machine

-

Plastic Auxiliary Equipment

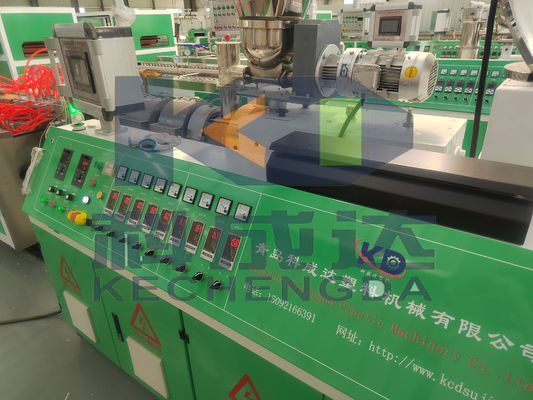

Interior WPC Bamboo Fiber Fluted Board PVC Coating Grille Indoor Great Wall Panel Extrusion Machine

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Screw Design | Double-screw | Screw L/D Ratio | 33:1 |

|---|---|---|---|

| Condition | New | Plastic Processed | PVC |

| Application | Sheet, Profile | Weight | 3624 KG |

| Warranty | 1 Year | Key Selling Points | Automatic |

| Applicable Industries | Hotels, Building Material Shops, Manufacturing Plant, Restaurant, Home Use, Retail, Construction Works , Advertising Company | Video Outgoing-inspection | Provided |

| Machinery Test Report | Provided | Warranty Of Core Components | 1 Year |

| Core Components | Screw | Screw Material | 38CrMoALA |

| Screw Diameter (mm) | 65 | Screw Speed (rpm) | 250 Rpm |

| Voltage | 220V | Dimension(L*W*H) | 20*1.5*3M |

| Power (kW) | 75 | Cooling Way | Water Cooling |

| Highlight | PVC Coating Grille Extrusion Machine,Great Wall Panel Extrusion Machine |

||

Product descriptions from the supplier

Interior Decoration WPC Bamboo Fiber Fluted Board PVC Coating Grille Indoor Great Wall Panel Extrusion Production Line

1. Twin Screw Extruder

Extruder adopts PVC ceiling dedicated screw, make sure best plastisizing effect.

Extruder speed and haul off speed controlled by ABB frequency converter, saving power and easy adjusting speed.

Extruder temperature adopt PLC control, temperature fluctuation self adjusting, it realize the high automatic level.

2. Mould

The mold determines the width and thickness of the final product, we can customize it according to your requirements

3.Vacuum Calibrating Table

Use vacuum system which could better achieve cooling accomplished results.

4. Hual-off Machine

5. Cutting Machine

Use wear-resisting saw blade to imcrease the sharpness and the working life.

| Model | Max Width | Power | Capacity |

| SJ 65/132 | 300 mm | 37 kw | 260 kg/h |

| SJ 80/156 | 600 mm | 55 kw | 400 kg/h |

| SJ 92/188 | 800 mm | 90/100 kw | 650 kg/h |